CERAKOTE® for Superalloys

Engineered Protection for Extreme Performance

Protect High-Performance Metals with Industry-Leading Ceramic Coatings

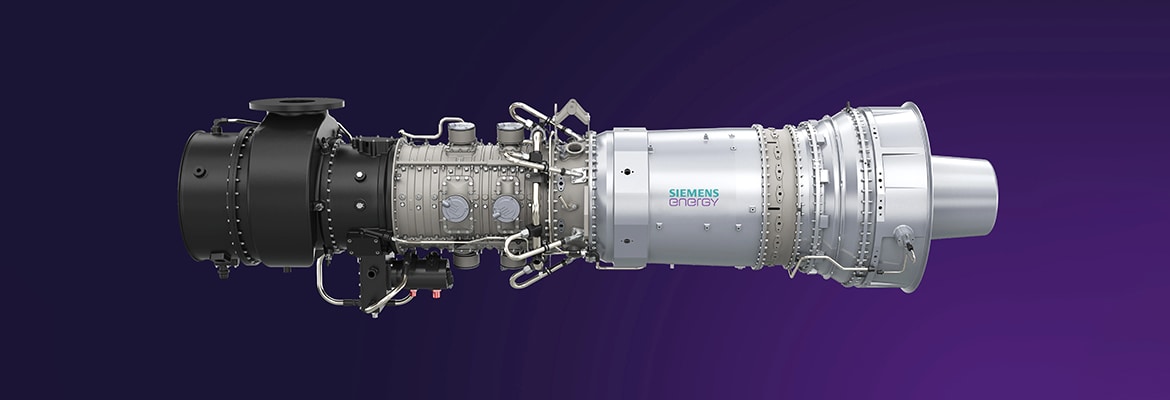

Superalloys are engineered to withstand the most punishing environments such as high heat, corrosion, stress, and fatigue. Found in aerospace, energy, defense, and motorsports, these advanced materials demand a coating that performs just as relentlessly.

Cerakote, a thin-film ceramic coating, offers unmatched durability, heat resistance, and corrosion protection for a wide range of nickel, cobalt, and iron-based superalloys, without compromising weight, tolerances, or mechanical properties.

Read on to learn more, or:

Contact our Account Manager Today

Why Cerakote Is the Perfect Match for Superalloys

Superalloys are strong—but not invincible. In aggressive operating environments, they are still susceptible to:

- Oxidation and scaling at high temperatures

- Corrosive gas and chemical exposure

- Abrasive wear and erosion

- Thermal cycling stress

Cerakote combats these challenges with:

- Extreme Heat Resistance: Ceramic stability at operating temps up to 1,800°F (538°C)

- Corrosion and Oxidation Resistance: Protects against harsh chemicals, salt spray, and atmospheric conditions

- Abrasive and Erosion Protection: Resists surface wear from friction, debris, and particulate exposure

- Ultra-Thin Film: Applied as thin as 0.5 to 2.0 mils, preserving tight tolerances

- Adhesion to High-Performance Metals: Engineered to bond to superalloys with proper surface preparation

- Custom Color & Finish Options: Matte, metallic, clear or high-temp finish options

Compatible Superalloy Families

Cerakote has been successfully applied to a variety of wrought and cast superalloys including:

- Inconel® (600, 625, 718, 738, 901)

- Hastelloy® (C-22, C-276, X)

- Monel® (400, K-500)

- Stellite® (6, 21, 31)

- Haynes® Alloys Alloys (25, 188, 230)

- A-286 (High strength, corrosion-resistant alloy for fasteners and structural parts)

- RA330® (Heat and corrosion-resistant alloy for furnaces and high-temp processing equipment)

Benefits of Cerakote on SuperAlloys

1. Elevated Corrosion Protection

In environments with complex chemical exposure, especially in chemical processing or offshore systems, Cerakote acts as an additional corrosion-resistant barrier. This is particularly valuable in threaded interfaces, weld zones, or crevice-prone geometries where corrosive agents may concentrate.

2. Thermal Stability

Cerakote high-temp formulations (e.g., C-Series) are rated for continuous exposure up to 1,800°F, providing surface oxidation control and thermal fatigue resistance on heat-critical components like Inconel exhaust housings or Hastelloy flanges.

3. Reduced Surface Wear and Galling

Many superalloys are prone to galling, a form of adhesive wear that can occur during assembly or in moving components under pressure. Cerakote low-friction surface reduces metal-to-metal contact issues, improving service life and disassembly reliability.

4. Enhanced Chemical Resistance

When paired with Hastelloy’s inherent resistance to strong acids and oxidizers, Cerakote offers an added chemical buffer, ideal for harsh processing environments or long-term storage conditions.

5. Surface Uniformity and Identification

Cerakote provides a consistent, durable finish in a range of colors and gloss levels, supporting part identification, system coding, or aesthetic preferences without compromising function.

Precision Meets Performance

Cerakote is trusted by engineers and manufacturers around the world for its ability to enhance the performance and longevity of mission-critical components, even under extreme heat, corrosive conditions, and mechanical stress.

Whether you're protecting an aerospace turbine blade or a custom-built racing turbo, Cerakote delivers where other coatings fall short.

Contact our experienced team today. We're here to answer your questions, provide technical support, and collaborate with you to find the perfect coating solution for your specific industry needs.

For more information you can call us at 866-774-7628 or email us at industrial@cerakote.com

Added To Cart

{{ itemJustAddedToCart.product.name }}

Amount:

{{ pricePerUnit }}

/unit

Quantity:

{{ data.quantity.value }}

{{ data.quantity.unit }}

{{ itemJustAddedToCart.product.name }}

Swatches are aluminum panels sprayed with Cerakote for DEMONSTRATION AND COLOR REPRESENTATION PURPOSES ONLY. If you desire a testing sample please contact us at info@cerakote.com If your order contains an "Out of Stock" swatch, we will create that swatch for you, then ship your entire swatch order. This can take up to two weeks.

If all swatches are IN STOCK it will ship in 1-3 business days via 2nd Day Air.

Items are Added to Your Cart